In the world of flat and low-sloped roofs, EPDM (ethylene propylene diene terpolymer) roofing membrane stands out as a reliable and versatile option. This synthetic rubber material offers exceptional resistance to harsh weather elements, making it a popular choice for building projects that prioritize durability and long-term performance. Let’s explore deeper about the composition, types, and maintenance needs of EPDM roofing membranes to see if they might be the perfect fit for your next project.

Table of Contents:

- Introduction to EPDM Roofing Membrane

- Composition of EPDM Roofing Membrane

- Types of EPDM Roofing Membrane

- Maintenance of EPDM Roofing Membrane

- Conclusion

Introduction to EPDM Roofing Membrane

So, what is EPDM Roofing Membrane? EPDM roofing membrane has earned its reputation for being a durable, flexible, and easy-to-install roofing solution. These advantages make it a compelling choice for both residential and commercial flat roof applications, offering significant benefits over traditional roofing materials.

Composition of EPDM Roofing Membrane

EPDM roofing membrane is made from a blend of synthetic rubber compounds: ethylene, propylene, and diene monomers. These ingredients are carefully combined through a process called vulcanization, where they’re chemically linked to form a strong and durable sheet.

- Ethylene: This component provides flexibility and elasticity, allowing the membrane to adapt to uneven roof surfaces without compromising its shape or integrity.

- Propylene: Propylene enhances the membrane’s resistance to heat and ultraviolet (UV) radiation, ensuring long-lasting performance even in harsh climates.

- Diene Monomers: These contribute to the membrane’s strength and resilience, making it resistant to punctures, tears, and abrasions.

The precise ratio of these elements is crucial for determining the EPDM membrane’s quality, durability, and weather resistance. Manufacturers carefully control this balance to achieve optimal properties and ensure the membrane meets industry standards.

Furthermore, EPDM roofing membranes may include additional additives and modifiers to enhance specific characteristics, such as fire resistance, thermal insulation, or color retention. These enhancements further improve the membrane’s performance and suitability for various roofing applications, making it a versatile and reliable choice for both residential and commercial projects.

Types of EPDM Roofing Membrane

EPDM roofing membranes come in several variations to suit different project needs. Understanding these types helps property owners make informed choices. Here’s a breakdown of the main options:

Reinforced vs. Non-Reinforced:

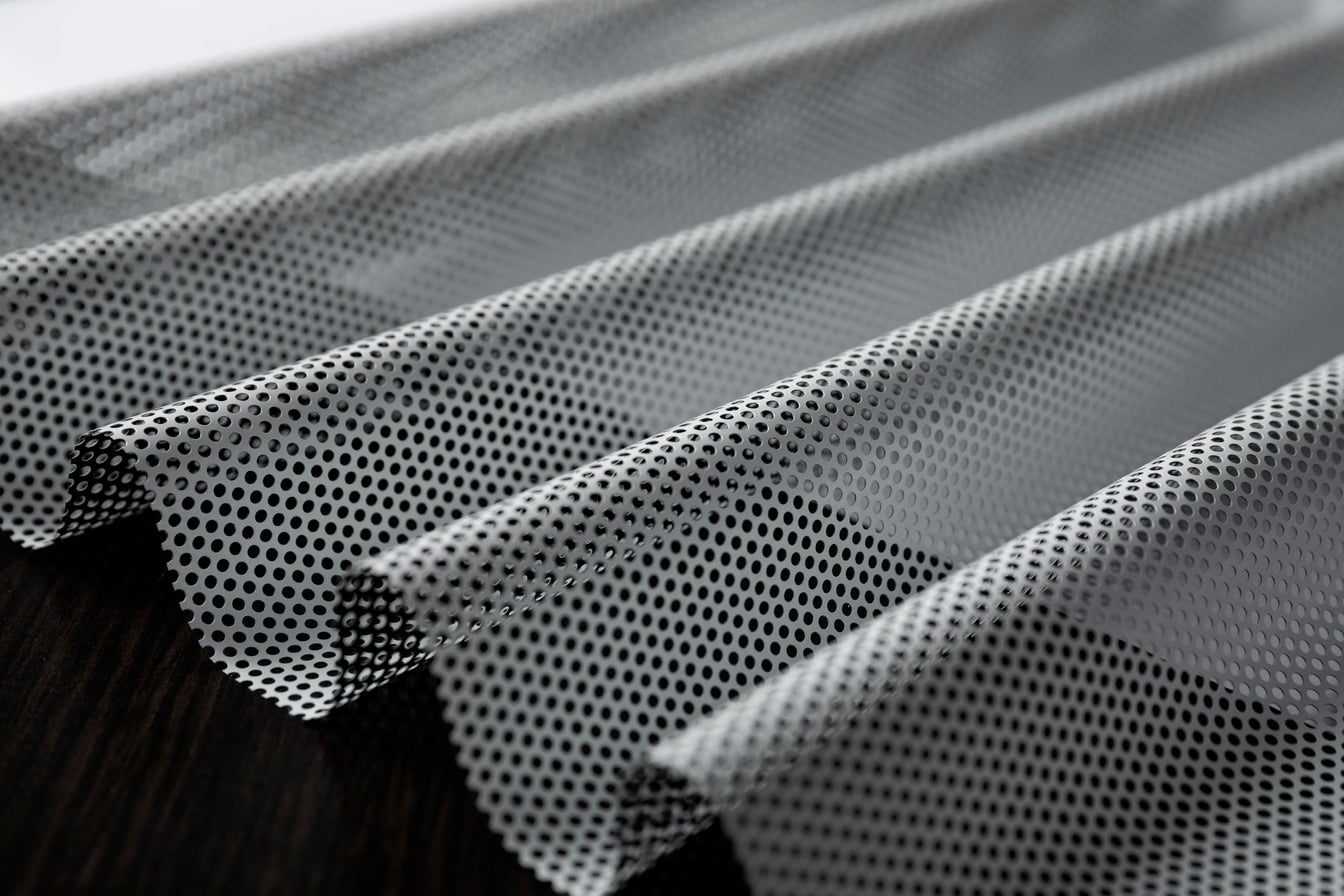

- Reinforced EPDM: This type has a layer of polyester or fiberglass mesh embedded within the rubber for added strength and stability. It’s more resistant to tears, punctures, and stretching.

- Non-Reinforced EPDM: This is the basic EPDM with only the rubber compound. It may be more affordable but is less durable and might change dimensions over time.

Standard vs. Mechanically Attached:

- Standard EPDM: These membranes are fully glued to the roof deck using adhesives. This method offers excellent waterproofing and wind resistance, making it ideal for low-slope and flat roofs.

- Mechanically Attached EPDM: These membranes are secured to the roof deck using fasteners like screws or nails. This allows for easier installation and thermal movement, making it suitable for larger roofs and areas with extreme weather.

Maintenance of EPDM Roofing Membrane

Proper maintenance is essential to maximize the lifespan and performance of your EPDM roofing membrane. Regular inspections and care can help you identify problems early and prevent costly repairs down the road. Here are some key maintenance tips:

Regular Inspection

Conduct routine inspections of the roof surface twice a year, ideally in spring and fall, to check for signs of damage, such as tears, punctures, or loose seams. Additionally, look for debris, vegetation, or standing water that could compromise the membrane’s integrity or lead to pooling.

Cleaning

Clean the EPDM membrane periodically to remove dirt, debris, and pollutants that can accumulate over time. Use a mild detergent solution and a soft-bristle brush to gently scrub the surface. Avoid harsh chemicals or abrasive cleaners, as they can damage the membrane.

Repairing Damages

Promptly address any damages or leaks identified during inspections to prevent water infiltration and structural problems. Use EPDM-compatible patching materials and adhesives designed specifically for this type of roofing to effectively seal tears, punctures, or seam separations.

Preventative Measures

- Trim overhanging tree branches or vegetation that could potentially damage the membrane during storms or high winds.

- Minimize foot traffic on the EPDM membrane, especially in cold weather, to prevent cracks or tears.

Professional Maintenance

Schedule regular maintenance visits with a qualified roofing contractor to have them assess the condition of the EPDM membrane and address any issues promptly. They can also recommend if applying a protective coating or sealant would be beneficial to enhance the membrane’s durability and weather resistance over time.

Conclusion

EPDM roofing offers a compelling combination of durability, flexibility, and ease of installation. Whether you’re a homeowner or a commercial property manager, EPDM membranes can provide a reliable and long-lasting roofing solution for your flat or low-slope roof. If you’re considering EPDM for your next project, Ener-Spray can help you navigate the different types and installation methods to ensure you get the best possible results. Contact Ener-Spray today for a free consultation and learn more about the benefits of EPDM roofing.