When people start planning a new home or building, energy costs, comfort, and long-term durability quickly become real concerns — especially once they realize how much those factors depend on choosing the right residential and commercial insulation from day one. That’s usually what leads them to search for insulation for new construction and compare different options before committing. This article will break down the essential role insulation plays in a modern building, explore the most common material options, and guide you through selecting the smartest choice to maximize comfort and save you money for the long term.

Table of Contents

ToggleWhy Insulation Matters in New Construction

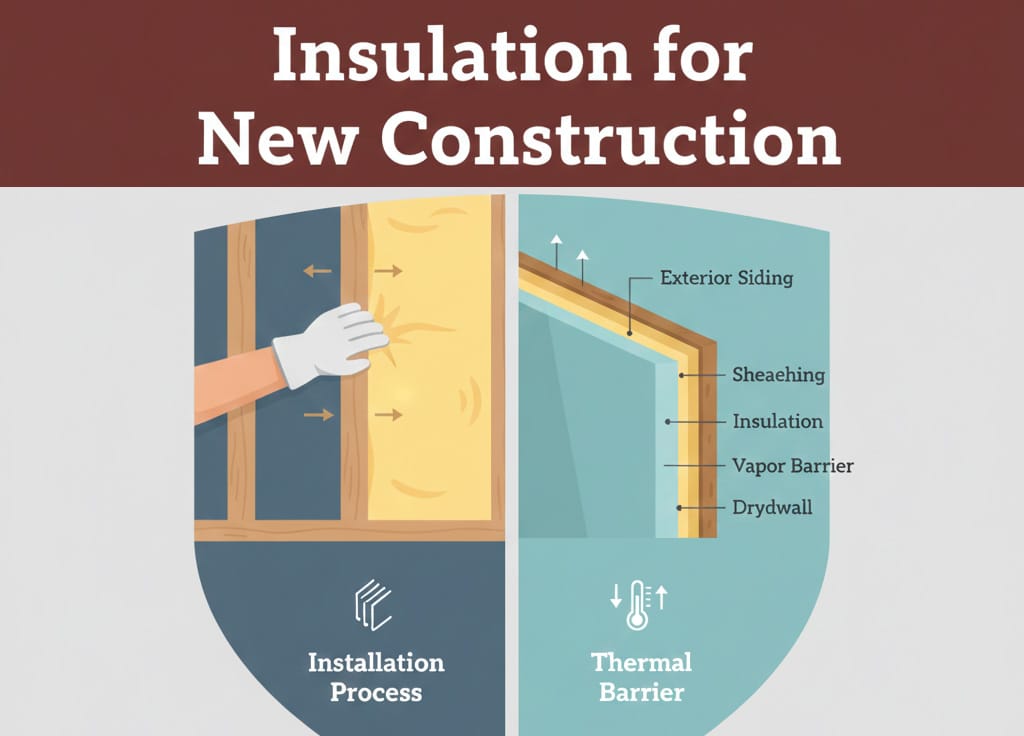

New construction insulation is often treated as just another building material, but it is fundamentally the most critical factor in determining a new structure’s long-term performance and efficiency. Unlike older buildings, new construction must meet stringent energy codes, and high-quality insulation is the primary way to achieve compliance while enhancing occupant experience.

When properly installed, insulation slows the transfer of heat across walls, floors, and ceilings. This simple action delivers significant benefits: it dramatically cuts down on the energy required to heat or cool the interior, stabilizes indoor temperatures to eliminate drafts and cold spots, and protects the building’s structural components by reducing moisture condensation within the walls. Essentially, insulation is the barrier that allows a modern building to function optimally, saving the owner money while providing superior comfort.

Common Types of Insulation Used in New Builds

When selecting insulation for new construction, you’ll encounter several common materials, each with its own advantages, cost profiles, and ideal applications. Understanding the basic options is key to making an informed choice.

Fiberglass batts

A traditional option that is cost-effective and widely available. It consists of pink, yellow, or white fibrous material (spun glass fibers) that are pre-cut into flexible batts (panels) or long rolls. They are affordable and easy to install, but they can leave gaps around wiring or framing if not fitted carefully.

Blown-in insulation

It is made from recycled paper, treated with fire-retardant chemicals, becoming an eco-friendly option with good fire-resistance. Often installed as a loose-fill material blown into wall cavities or attics, it offers better coverage in irregular spaces and provides solid thermal performance, though it can settle over time.

Rigid foam boards

These are panels made from expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate (Polyiso). They are typically used on exterior sheathing or under concrete slabs. They add strong insulation value with a thin profile, making them useful for exterior walls or foundation areas where space is limited. However, they require careful insulation installation to avoid air leakage at seams.

Spray foam insulation

Spray foam insulation remains one of the highest performing systems for new construction. It provides the most complete air seal and highest overall performance, expanding to fill every crack and gap for maximum efficiency.

Spray Foam Insulation: A Leading Choice for Modern Projects

For many new construction projects, spray foam insulation offers advantages that are difficult to match. Ener-Spray Group specializes in applying high-performance spray foam systems as energy-efficient building insulation that combine insulation, air sealing and moisture regulation in one step.

The main advantage of spray foam is its ability to create a monolithic (seamless) air barrier. When sprayed, it expands to fill every crack, gap, and void, completely enveloping plumbing, wiring, and irregular framing. This total sealing capability eliminates air leakage—the single greatest cause of energy loss in any building—making it the smart choice for maximizing comfort and achieving long-term energy savings.

There are two primary types of spray foam used in new builds:

Open-Cell Foam

This foam is lighter, less dense, and expands dramatically. Open-cell spray foam is used in interior spaces where sound absorption and flexibility are priorities. Both forms of spray foam support energy-efficient design and help reduce long-term heating and cooling expenses. Builders looking for a modern, durable and high-performing solution often choose spray foam for new construction insulation.

Closed-Cell Foam

Its closed-cell structure provides one of the highest R-values available per inch. This helps achieve strong thermal performance while keeping wall assemblies thinner. Closed-cell spray foam also creates an effective moisture barrier, reducing the risk of condensation forming inside the walls. This is especially valuable in Canadian climates where temperature swings are common.

Ener-Spray Group provides full installation services and supports contractors through every step of the project.

How to Choose the Right Insulation for Your Project

Selecting insulation for new construction depends on several factors, including the climate, the structure of the building and the performance expectations of the owner. It is important to consider the R-value requirements for the region, moisture control needs, building codes and long-term energy goals.

For high-performance buildings, spray foam insulation often gives the best results because it eliminates many of the common issues associated with conventional insulation. However, some projects benefit from combining different insulation types to address unique design elements.

Working with specialists ensures that the insulation plan supports both the architectural layout and the practical needs of the finished building. Ener-Spray Group evaluates every project individually and recommends solutions that balance efficiency, comfort and cost-effectiveness.

Conclusion

The decision regarding insulation for new construction is perhaps the most critical long-term investment you will make in your new build. As this guide has demonstrated, choosing a high-performance system is the definitive answer to the pain points of high utility bills, drafty rooms, and moisture-related structural risks that plague conventionally insulated buildings. By prioritizing advanced materials like spray foam, you secure decades of predictable energy savings and superior occupant comfort.

If you are currently planning a new project and are looking for professional guidance to ensure your building achieves the highest possible thermal envelope, don’t leave the most critical component to chance. Secure the “smart upgrade” that delivers long-term savings and comfort. Reach out to Ener-Spray Group today to discuss your new construction insulation needs and request a project-specific evaluation.